数据驱动超纯水制备过程与原理探究专注于铁锰过滤设备的应用

数据驱动:超纯水制备流程与原理分析,专注于铁锰过滤设备的应用

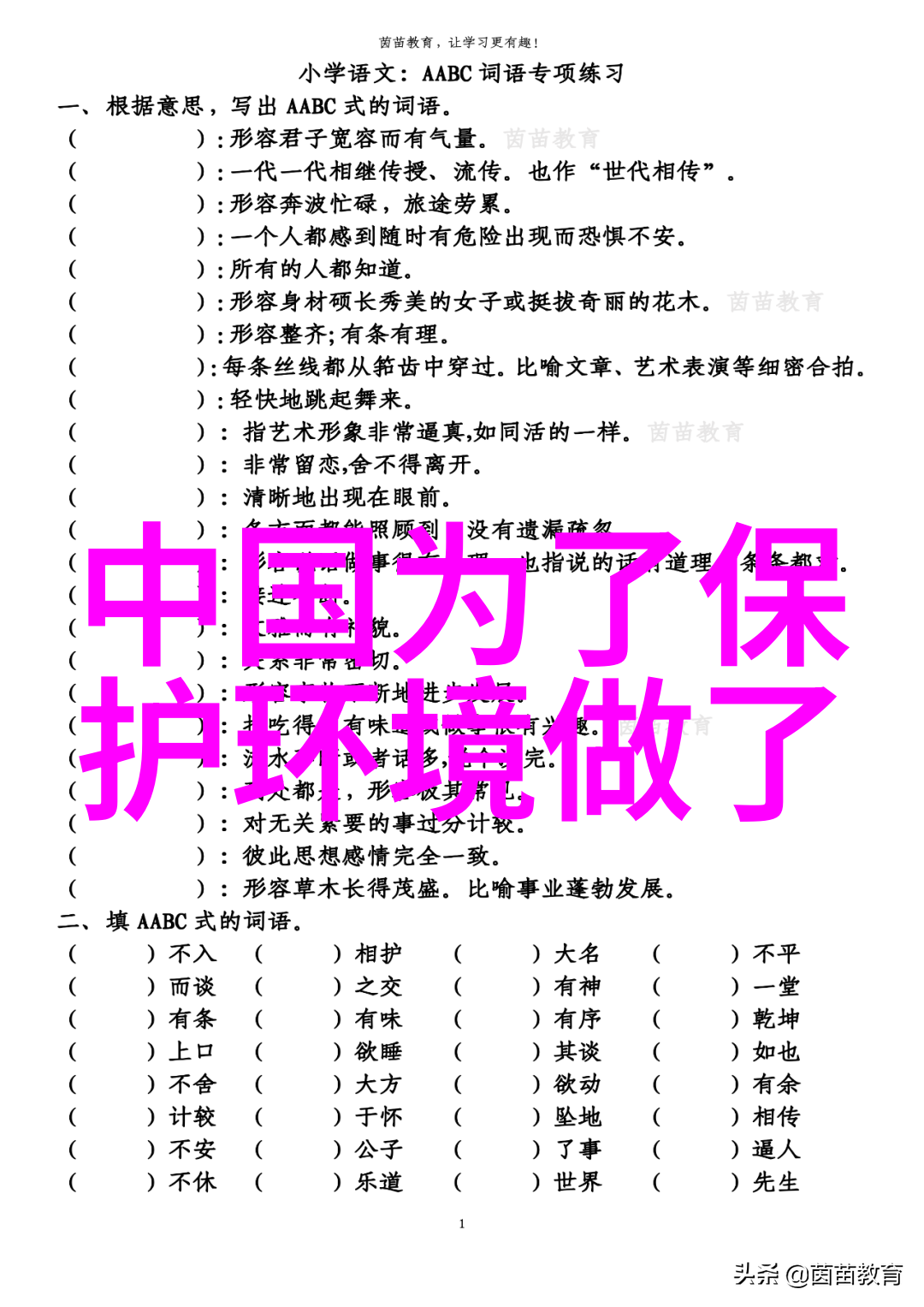

超纯水制备主要包括三个阶段,即初步吸附过滤、反渗透净化和树脂离子交换。中文名为“超纯水”,其电导率小于20uS/cm,电阻率大于10MΩ·cm。

设备包括原水泵、高压泵、活性炭过滤器等。生产操作中需检查设备无异象,并确保各连接管之间封闭,以防止滴漏。在开启总电源并逐步启动原水泵和高压泵后,需要观察设备运行情况,确保每个过滤设备进出口水压差在一定范围内(小于0.1MPa),同时控制RO进水、中段、浓水的压力在要求范围内,以保证RO产水的电导率小于20uS/cm。

当装用超纯水时需开启增压泵,并打开第一个出water阀。此过程中需注意混床进出water pressure及精密过滤器pressure及混床outwater pressure均在要求范围内,以保证outwater的electric resistance rate大于10MΩ·cm。在此期间还需注意观察pure water tank中的存water情况,不得抽空!同时,为防止存water过多导致water quality变差影响mixing bed resin life,must control the water in the mixing tank below the float.

使用完毕后应关闭好总power supply, close original water inlet valve and pure water outlet valve, to prevent reverse flow of tap water and air into filtration devices for damage.

超纯Water Production Process Principle

Initial Absorption Filtration Stage includes honeycomb filter, activated carbon filter, compressed activated carbon filter, and safety filter.

a. Honeycomb Filter's main function is to remove particulate matter larger than 10um from raw water.

b. Activated Carbon Filter's main function is to utilize its excellent adsorption properties to capture chlorine gas and small molecular organic compounds in raw water along with the filter core.

c. Compressed Activated Carbon Filter uses stronger adsorption properties than activated carbon to further remove chlorine gas and small molecular organic compounds from raw water, ensuring that reverse osmosis (RO) feed meets requirements.

d. Safety Filter also removes particulate matter larger than 5um from raw water before RO feed, further ensuring RO product quality.

来源:百度百科